Built to Endure: The Art of Traditional Joinery

Understanding Wood Movement

Why Mechanical Locks Beat Metal Fasteners

Dovetails, Tenons, and the Cases They Serve

Through and Half-Blind Dovetails

Through dovetails broadcast their strength with exposed pins and tails, perfect for case corners or visible utility pieces. Half-blinds hide their joint at the front, ideal for fine drawers where clean faces matter. Both resist pull apart forces brilliantly when laid out with thoughtful ratios, baseline accuracy, and crisp shoulders. Practice sawing to the line, pare only when necessary, and learn to read tail-first versus pin-first workflow. Soon, your dry fits will click like a well-tuned instrument.

Mortise-and-Tenon Variations That Matter

Through dovetails broadcast their strength with exposed pins and tails, perfect for case corners or visible utility pieces. Half-blinds hide their joint at the front, ideal for fine drawers where clean faces matter. Both resist pull apart forces brilliantly when laid out with thoughtful ratios, baseline accuracy, and crisp shoulders. Practice sawing to the line, pare only when necessary, and learn to read tail-first versus pin-first workflow. Soon, your dry fits will click like a well-tuned instrument.

Rabbets, Dados, and Sliding Dovetails in Casework

Through dovetails broadcast their strength with exposed pins and tails, perfect for case corners or visible utility pieces. Half-blinds hide their joint at the front, ideal for fine drawers where clean faces matter. Both resist pull apart forces brilliantly when laid out with thoughtful ratios, baseline accuracy, and crisp shoulders. Practice sawing to the line, pare only when necessary, and learn to read tail-first versus pin-first workflow. Soon, your dry fits will click like a well-tuned instrument.

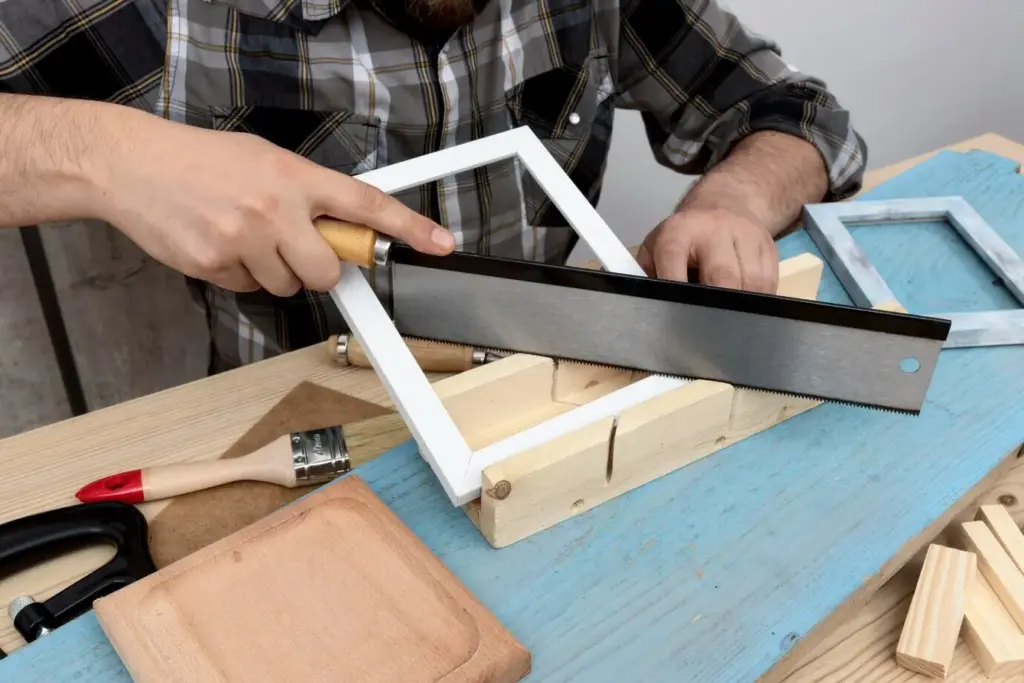

Layout, Tools, and Repeatable Accuracy

Choosing Species for Cabinetry and Built-Ins

Consider hardness, pore structure, and stability. White oak resists wear and offers ray-fleck elegance, cherry mellows into warm character, and maple’s fine grain makes drawers smooth and strong. Use stable sheet goods for carcases when appropriate, but anchor with solid lippings or face frames. Mix species thoughtfully to manage cost without compromising performance. Match fasteners and finishes to wood density, and remember that color shifts over time. Plan for that living patina, not against it.

Reading Grain for Strength and Beauty

Grain is a map of stresses and possibilities. Turn cathedrals consistently for harmony, reserve straight grain for rails and stiles, and avoid short grain near joinery shoulders. Glue faces should present long fibers whenever possible. Bookmatch panels where it flatters the piece, not just to show off. Your chisel will tell you when grain direction is right; listen to the cut, the feel, and the curl. Strength and elegance grow from the same careful observations.

Glue Choices, Open Time, and Clamping Strategy

Hide glue offers reversibility and graceful creep control, while PVA can provide forgiving open time for complex assemblies. Epoxy shines when gaps or exterior exposure demand it. Whatever you choose, design clamps as part of the joint: opposing forces, cauls that spread pressure, and pads protecting edges. Dry fit with witness marks, rehearse your sequence, and stage tools. Calm timing beats panic every time, producing cured joints that feel relaxed rather than forced.

Designing Cabinetry and Built-Ins for Everyday Life

Shop Stories, Lessons, and Your Turn

A Drawer That Refused to Stick

Sliding Dovetails Keep a Library Square

All Rights Reserved.